A Comprehensive Overview to Comprehending Litho Printing Techniques

The globe of litho printing, a method stemming from the late 18th century, is a fascinating blend of background, science, innovation and art. Stay with us as we trip right into the fascinating realm of litho printing.

The Historical Development of Litho Printing

The historical trajectory of litho printing, a critical innovation in the world of interaction, is an exciting story of human resourcefulness. Birthed in the late 18th century by Alois Senefelder, this strategy was at first a cost-effective technique of publishing theatrical works. Lithography, originated from the Greek words for 'rock' and 'to compose', utilized a smooth stone surface area to transfer pictures onto paper. The process progressed with the arrival of the rotating press, which significantly raised productivity (litho printing). In the 20th century, the development of balanced out lithography changed the market, permitting for mass production of top quality prints. Each phase of litho printing's development showcases mankind's relentless quest of performance and top quality in visual interaction.

Deciphering the Scientific Research Behind Litho Printing Inks

Progressing in the expedition of litho printing strategies, the focus now shifts to the scientific research behind litho printing inks. The make-up of these inks, their drying process, and color mixing strategies develop the foundation of this complicated art form. Recognizing these components is vital to mastering the craft and accomplishing the desired print outcomes.

Structure of Litho Inks

In lithographic printing, the fundamental duty of litho inks can not be overstated. The structure of litho inks varies depending on its function, but normally, they include two main elements - pigments and cars. Pigments, the color-providing elements, are finely ground particles put on hold in the car, a fluid that brings the pigment onto the printing surface. The lorry is a complicated blend of solvents, resins, and oils, which influence the ink's drying out time, adhesion, and gloss. Furthermore, various additives exist to improve particular residential properties like flow, drying, and resistance to ecological effects. Each component plays a crucial component in the last print's top quality, making the exact solution of litho inks a complex scientific research.

Ink Drying Refine

From the composition of litho inks, focus transforms to the fascinating process of ink drying out. The drying procedure is vital, as it influences the last print's high quality and long life. 2 key techniques are used in litho printing: oxidative drying and absorption. Oxidative drying includes the ink reacting with oxygen airborne to develop a difficult, completely dry movie. This technique supplies a long lasting surface, however can be slower contrasted to absorption. Absorption, on the various other hand, entails the ink permeating right into the paper fibers, which is a much faster procedure yet can bring about less vibrant colors. The choice in between these approaches is reliant upon factors such as print rate needs, the paper kind utilized, and the desired surface.

Color Mixing Methods

While the drying out process plays a key duty in litho printing, the scientific research of color blending strategies holds equal relevance. This is an intricate procedure that entails the careful mixing of primaries: cyan, magenta, and yellow, in differing proportions to achieve a vast selection of tones. The addition of black ink, understood as 'vital', assists in regulating the intensity and deepness of the shades. The science behind litho printing inks additionally takes into account the transparency of the ink, which influences just how shades overlay and mix. Homepage To achieve an effective color mix, print professionals should additionally understand the details of ink actions, shade concept, and the physical residential or commercial properties of the substratum on which the ink is applied.

The Art and Design Components in Litho Printing

Litho printing takes a breath life right into art and style via its special elements. Litho printing accommodates a variety of shades, allowing musicians to develop dynamic and dynamic prints. This combination of precision and versatility makes litho printing a preferred option for several artists and designers.

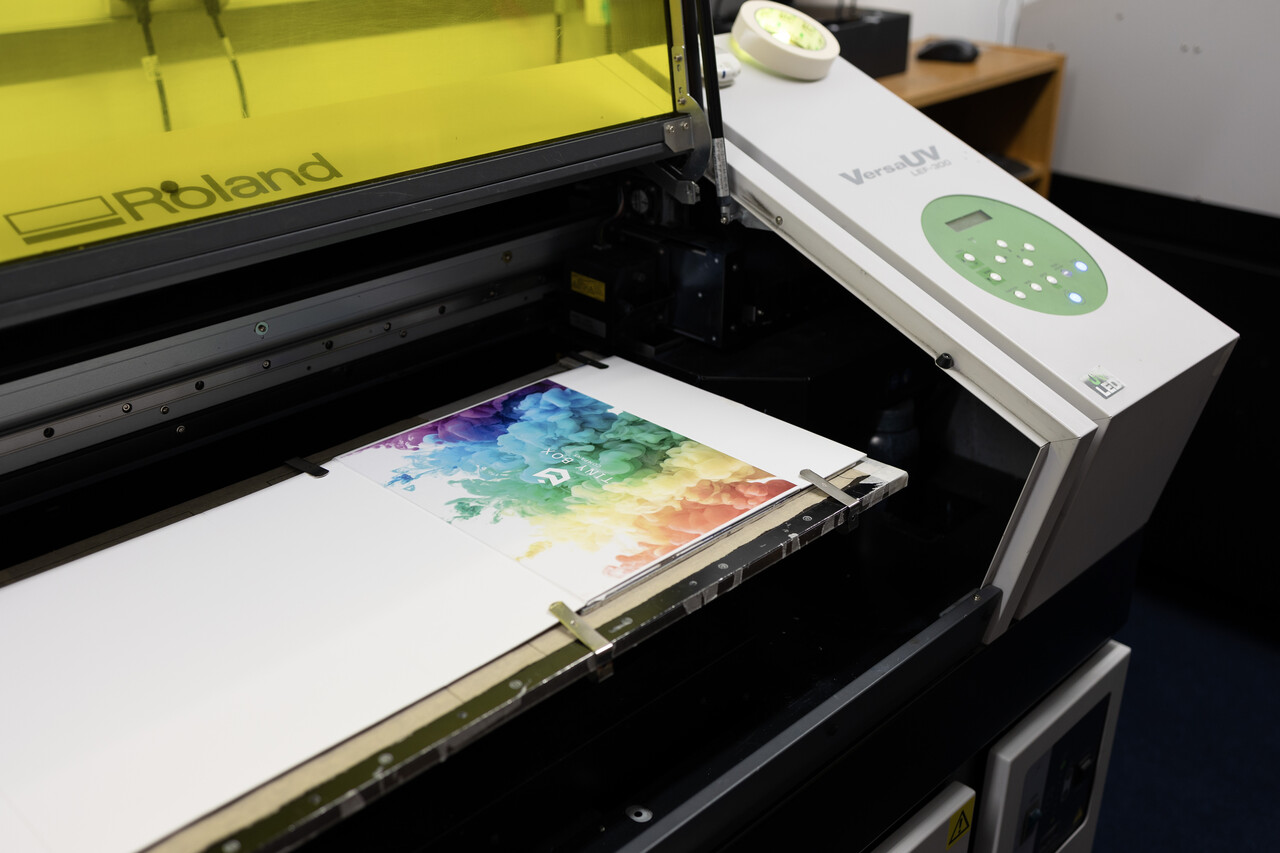

Modern Applications of Litho Printing Methods

Litho printing methods have actually found comprehensive use in the modern business field. Its influence and importance continue to expand with the introduction of brand-new technologies and modern technologies in the field. This area will check out these modern applications and the transformative function they play in the printing sector.

Commercial Litho Printing Uses

In today's digital age, one might wonder about the significance of standard printing methods. Yet, litho printing continues to be a vital component of the commercial sector. High-volume printing jobs, such as the manufacturing of books, newspapers, and packaging, count on litho printing for its capability to provide remarkable image high quality and price effectiveness. The process, which involves moving a tattooed picture from a plate onto a rubber blanket and afterwards to the printing surface area, offers unequaled consistency. This makes it suitable for jobs needing a large print run. Litho printing likewise gives a wide shade spectrum, above that of electronic printing. This makes it the best selection for projects that demand lively, high-grade color reproduction.

Advancements in Litho Printing

Pressing the borders of typical techniques, modern advancements have fueled a host of innovations in litho printing. These developments have not only enhanced the top quality and effectiveness of litho prints but also expanded its application range. One popular development is digital litho printing, which combines the merits of digital innovation with litho's top quality result. This hybrid design offers faster configuration times, reduced waste, and enables on-demand printing. One more notable improvement is the introduction of environmentally pleasant inks. These inks, made from veggie or soy-based solutions, have actually dramatically minimized the industry's environmental effect. litho printing. Furthermore, the growth of innovative plate modern technology has streamlined the printing procedure, leading to sharper images and enhanced color integrity. These developments highlight the long-lasting relevance of litho printing in the modern-day world.

Discovering the Process of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

Despite the accuracy and tradition that litho printing happily upholds, it is not without its set of my review here contemporary challenges. Digital litho printing enables for cost-efficient short runs and easy customization, resolving the problem of variable information. Thus, while there are obstacles, the litho printing industry is proactively adjusting to satisfy them head-on, ensuring its relevance in the future.

Final thought

In final thought, litho printing, with its abundant background and scientific intricacies, holds a substantial area in the print industry. The future of litho printing hinges on its capability to adapt to these altering needs, attesting its long-lasting worth in a developing market.